Products

MIXER

STRUCTURE FEATURES:

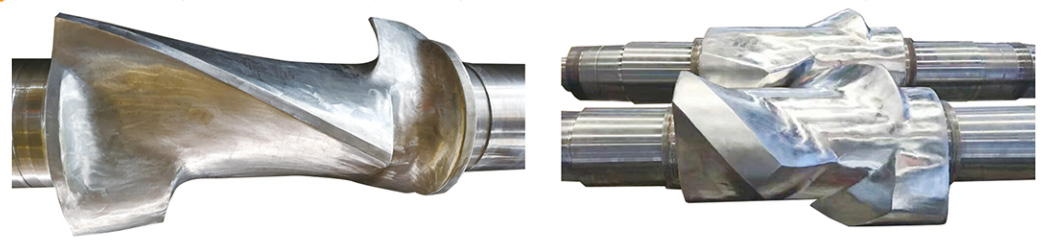

Different type of rotors can satisfy the mixing technical requirement.IRotor chamber, discharge door and ram are circulation-cooled.With TCU,it can quarantee the quality of mixenrub-2ber compound.

Touch surface of rotor,chamber,discharge door,ram and other contacting parts with mixing rubber are plantedwithchrome or wear-resistan hard metal.iHydraulic type sealing steucture guarantees the closed grain of the adHesive materials.5 Upper ram is hydraulic or pneumatic pressure type,which can control the press continuously.(6 The floating weight is falling type,driven by gear and hydraulic oil tank with good sealing performance.7Various driving system matchs the customersrequirement8 This machine adopts intelligent control system, equipped with rubber mixing process according to product require.ments arbitrary control mode setting function, suitable for any diferent rubber material or different operators differ.ent reauirements, product auality and efficiency standards unified, The control svstem adonts the touch screen (thenecessary operation buttons and switches outside the PLC man-machine interface are equipped with flat-headbutton switches) and the programmable controller touch screen can effectivelv transmit and displav the operationof the host, and can also set different pressure and speed according to different rubber materials.

The control system stores a variety of process programs, and adiusts the appropriate process in real time according tothe process requirements. To achieve the effect of automatic rubber mixing, and can record the results of rubber mixingwithin a week.check the unqualified products.10 it can be seamlessly connected with the upstream system to realize the automation of rubber mixing.