Products

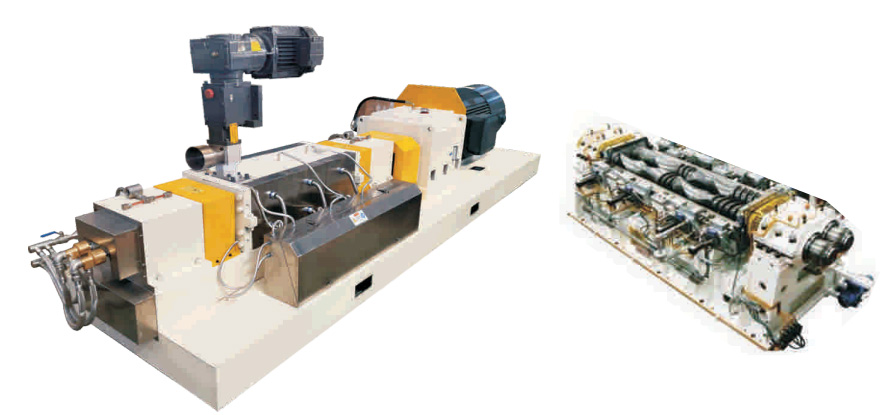

Continuous-Banbury-Mixer

The Continuous banbury mixer applys in:

It is suitable for the mixing and aranulation of PP, PE, ABS, PS etc Masterbatch, flame retardant, talcum powder, calciumcarbonate, titanium dioxide, carbon black, organic and inorganic pigments, wood and plastic filling modification,

thermoplastic elastomer, rubber-modified masterbatch, blend masterbatch, wire and cable special material and sheathincmaterial,Rubber desulfurization and modification and has the advantages of uniform mixing and strong filling ability, simpleprocess, high mixing capacity. With smallfootprint, it can save energy and the costs of installation and maintenance.

Environmental and enery saving, well mixed, high filling alibility, simple process, high automation

The Continuous banbury mixer advantages

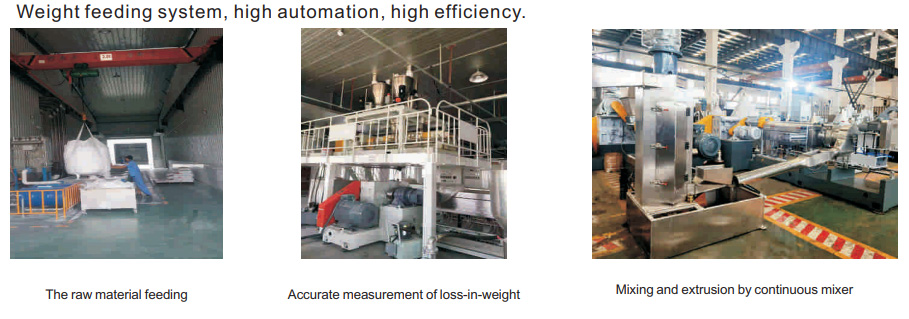

1.Adopt advanced Loss-in-weight feeding system, high automation, high efficiency.

2. Continuous production, stable formula production state, good quality product .

3. Continuous operation requires fewer operators.

4. The clean environment of masterbatch production workshop.

5. Strong ability for Screw barrel self-cleaning , convenient to change the materials.

6. More energy saving and higher output.

7. Superior mixing effect, better dispersion.

8. Low cost for installation and maintenance.