Products

RB series high-speed steel wire spiral twisting machin

This machine is a new high-speed steel wire winding machine designed by our company. It uses the latest on-machine molding technology, under-machine CNC pre-adjusted force design, and full CNC control (PLC + human-machine interface + servo drive) to improve winding accuracy and ensure high-quality, high-speed winding. The machine is designed for foolproof operation to address issues of winding stability in hose production. It features independent parting of the winding mold, digital control of force, full servo closed-loop digital control, and fixed production data, ensuring consistent product quality regardless of operator skill or responsibility. This machine is patented by our company (Patent No. ZL201821037852.8).

Key Components:

-

Winding Main Machine: The main machine is servo motor-driven, with spindles on a winding turntable. It uses a single-filament pay-off structure for consistent tension and stable production. Steel wire is preformed and evenly wound onto the rubber tube.

-

Small Cloth Winding: A servo motor-driven cloth winding mechanism, with two unwinding systems for mesh cloth and rubber sheet. Adjustable tension control ensures consistent unwinding.

-

Steel Wire Forming: A single-wire forming mechanism with a multi-piece structure that prevents wires from crossing and ensures even force distribution.

-

Traction Machine: A servo-driven mechanism that pulls the tube at a set speed, using a 4-track guide to reduce friction and improve traction. The AB sub-matrix combination increases grip and avoids product quality issues caused by turning the tube.

-

Digital Control: The winding machine uses full servo closed-loop control (touch screen, PLC, and servo motor) to precisely control winding pitch. The operator simply sets the pitch through the touch screen, and the system adjusts the servo motors to maintain the correct speed ratio for winding. It also allows storage of preset production settings for different processes, ensuring easy operation and consistent product quality.

-

Steel Wire Conductor: The wire winding spool is controlled digitally, allowing operators to set parameters such as wire pitch, speed, and length for easy operation.

-

Tension Detection: The machine includes high-accuracy tension detection (±0.04KG) to ensure proper spindle tension before each winding operation. This feature ensures quality control through digital management, rather than relying on experience.

-

Safety Protection: The equipment includes a safety door monitoring system. If the safety door isn’t closed, the machine won’t start, and it will stop if the door is opened during operation, reducing safety risks.

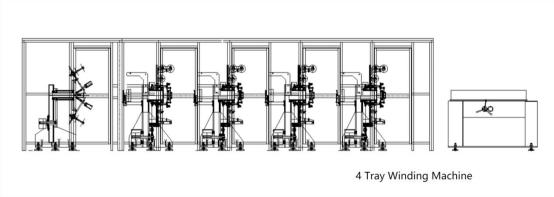

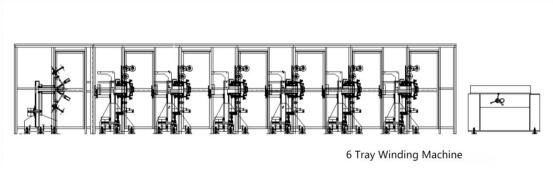

Equipment plan layout:

Main technical parameters and quotation

|

Equipment name Technical specifications |

30 Spindles High Speed Four Tray Winding Machine |

42 Spindle High Speed Four Tray Winding Machine |

|

|

1 |

Equipment Model |

RB30-4S |

RB42-4S |

|

2 |

Winding speed |

7m/min |

7m/min |

|

3 |

Winding stroke |

35—175mm |

35— 175mm |

|

4 |

Control form |

Digital automatic control |

Digital automatic control |

|

|

|

(PLC + human-machine interface) |

(PLC + human-machine interface) |

|

6 |

Drive type |

Full servo drive |

Full servo drive |

|

7 |

Total power |

40.5kw |

40.5kw |

|

8 |

Pre-forming form |

In-machine molding |

In-machine molding |

|

9 |

Preformed wire shape |

Expanded |

Expanded |

|

10 |

Unwinding force error |

±0.04kg |

±0.04kg |

|

11 |

Unwinding form |

Single release wire |

Single release wire |

|

12 |

Applicable wire diameter (maximum) |

0.6mm |

0.6mm |

|

13 |

Spool capacity |

20KG/group (4 groups) |

20KG/group (4 groups) |

|

14 |

Spool structure form |

Multi-spool combination structure |

Multi-spool combination structure |

|

15 |

Hose winding range |

Φ10- Φ25 (spool = 4 groups) |

Φ10- Φ25 (bobbin = 4 groups) |

|

|

|

|

φ25- φ51 (spool = 4 groups) |

|

|

|

|

Φ25- φ76 (spool = 5 groups) |

|

16 |

Number of winding layers at a time |

4 layers |

4 layers |

|

17 |

Number of matched spools (standard) |

240 sets |

240 sets |

|

|

Center height |

1270mm |

1270mm |

|

18 |

Protection form |

Fully enclosed protection room |

Fully enclosed protection room |

|

19 |

Dimension mm |

12100*2100*2630 |

12100*2100*2630 |

Operation control functions:

1、Door control start/stop alarm function

2 、No automatic stop function in the rubber detection

3 、Digital control function of cloth winding up force

4 、Function of fixed length knitting

5 、Equipment failure prompt self-test function

6 、Three color alarm function

7 、All servo closed-loop control

8 、Independent storage of winding formula

9 、Production process data operation

Sub-item quantity and description:

|

No. |

Description |

Specification / Model |

Qty |

Unit |

Remarks |

|

1 |

Winding and hauling machine |

RB-1200 |

1 |

table |

|

|

2 |

Winding Turntable |

RB30-4S |

4 |

table |

|

|

|

|

RB42-4S |

4 |

table |

|

|

3 |

Winding small cloth machine |

RB-200 |

1 |

table |

|

|

4 |

Special tension adjuster |

ZL-6 |

1 |

table |

|

|

5 |

Spools for winding |

RB-4Z |

2 |

set |

|

|

6 |

Safety shield |

Acrylic version |

1 |

set |

|

|

7 |

Electrical control cabinet |

Delta Systems |

1 |

set |

|

|

8 |

Common tools / wearing parts |

|

1 |

set |

|

|

9 |

Instruction manual |

|

1 |

copy |

|

Product Configuration:

|

No. |

Part Name |

Specification/model |

Accessory brand |

Remarks |

|

1 |

Winding host |

RB30-4S |

Jinzhong Machinery |

|

|

|

|

RB42-4S |

Jinzhong Machinery |

|

|

2 |

Traction machine |

RB |

Jinzhong Machinery |

|

|

3 |

Traction servo motor |

7.5KW |

Taiwan Delta |

|

|

4 |

Main tray servo motor |

7.5KW |

Taiwan Delta |

|

|

5 |

Up force adjustment machine |

GS-6 |

Jinzhong Machinery |

|

|

6 |

Touch screen |

10 寸 |

Taiwan Delta |

|

|

7 |

PLC programmable controller |

28SV |

Taiwan Delta |

|

|

8 |

Push button |

|

Schneider France |

|

|

9 |

Relay |

|

Schneider France |

|

|

10 |

Control program |

RB |

Jinzhong Machinery |

|

|

11 |

CNC Wire Machine |

RB |

Jinzhong Machinery |

|

|

12 |

Electrical switches |

|

OMRON |

|