Products

SCG-B series CNC hard-core nylon cloth wrapping and unwrapping machin

This machine is a new type of hard core method wrapping and unwrapping nylon cloth machine independently developed and designed by our company. The machine adopts a central winding form, and the structure of this form greatly improves the loading capacity of nylon cloth. At the same time, the operating speed of the equipment has also been improved, with a maximum main disc speed of 450r/min, greatly improving the work efficiency of hard core production. Equipped withautomatic digital control, it can achieve automatic entanglement of nylon cloth, reduce the operational skills of employees, and improve the stability of product production. The tension control adopts a pneumatic tension control mechanism, greatly improving the uniformity and consistency of the fabric tension, thereby improving the appearance quality of the product.

Equipment application: Used for wrapping before vulcanization and unwrapping after vulcanization. The entanglement of water cloth can be completed using a common device.

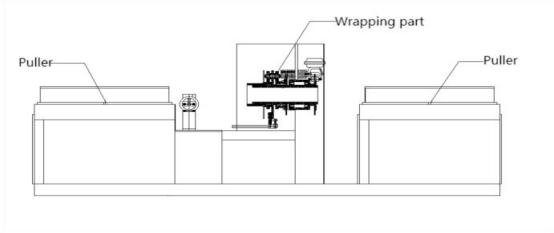

Layout drawing:

Main technical parameters:

|

Equipment name Technical specifications |

150 hard-core nylon cloth wrapping and unwrapping machine |

350 hard-core nylon cloth wrapping and unwrapping machine |

|

|

1 |

Model |

SCG-150-B |

SCG-350-B |

|

2 |

Equipment speed( r/min) |

450r/min |

450r/min |

|

3 |

Mode of production |

Hard core production |

Hard core production |

|

4 |

Spindle through-hole diameter (mm) |

150mm |

350mm |

|

5 |

Wrapping range |

φ10-φ102 |

φ76-φ152 |

|

6 |

Control form (Wrapping) |

Digital automatic control |

Digital automatic control |

|

(PLC+human-machine interface) |

(PLC+human-machine interface) |

||

|

7 |

Control form (Unwrapping) |

Digital automatic control |

Digital automatic control |

|

(PLC+human-machine interface) |

(PLC+human-machine interface) |

||

|

8 |

Drive mode |

Variable frequency motor |

Variable frequency motor |

|

9 |

Total power |

7kw |

11.5kw |

|

10 |

Cloth loading form |

Central loading |

Central loading |

|

11 |

Tension control |

Pneumatic |

Pneumatic |

|

12 |

Traction structure form |

Horizontal type |

Horizontal type |

|

13 |

Traction track structure |

Rubber block type |

Rubber block type |

|

14 |

Wrapping pitch( mm) |

30-70 |

30-70 |

|

15 |

Central height( mm) |

1050mm |

1350mm |

|

16 |

Number of puller |

2 sets |

2 sets |

|

17 |

Maximum diameter( mm) |

φ500 |

φ500 |

|

18 |

Protection type |

Semi protective |

Semi protective |

|

19 |

Dimension (mm) |

4000× 1150 × 1577 |

5377 × 1480×2084 |

|

(L*W*H) |

(L*W*H) |

Machine configuration:

|

No. |

Description |

Model |

Qty |

Unit |

Remark |

|

1 |

Nylon cloth wrapping and unwrapping machine |

|

1 |

set |

|

|

2 |

Electrical control cabinet |

|

1 |

set |

|

|

3 |

Water cloth cover |

|

4 |

piece |

|

|

4 |

Common tools/vulnerable parts |

|

1 |

set |

|

|

5 |

Operation instructions |

|

1 |

piece |

|

Brand list:

|

No. |

Description |

Model |

Brand |

Remark |

|

1 |

Host |

|

Jinzhong, China |

|

|

2 |

Frequency converter |

|

Delta, Taiwan |

|

|

3 |

Electrical machinery |

|

Lichao, China |

|

|

4 |

PLC |

|

Delta, Taiwan |

|

|

5 |

Touch Screen |

|

Delta, Taiwan |

|

|

6 |

Reducer |

|

Guomao, China |

|

|

7 |

Control program |

|

Jinzhong, China |

|

|

8 |

Button |

|

Schneider |

|

|

9 |

Relay |

|

Schneider |

|

|

10 |

Air cylinder |

|

AirTAC |

|