Products

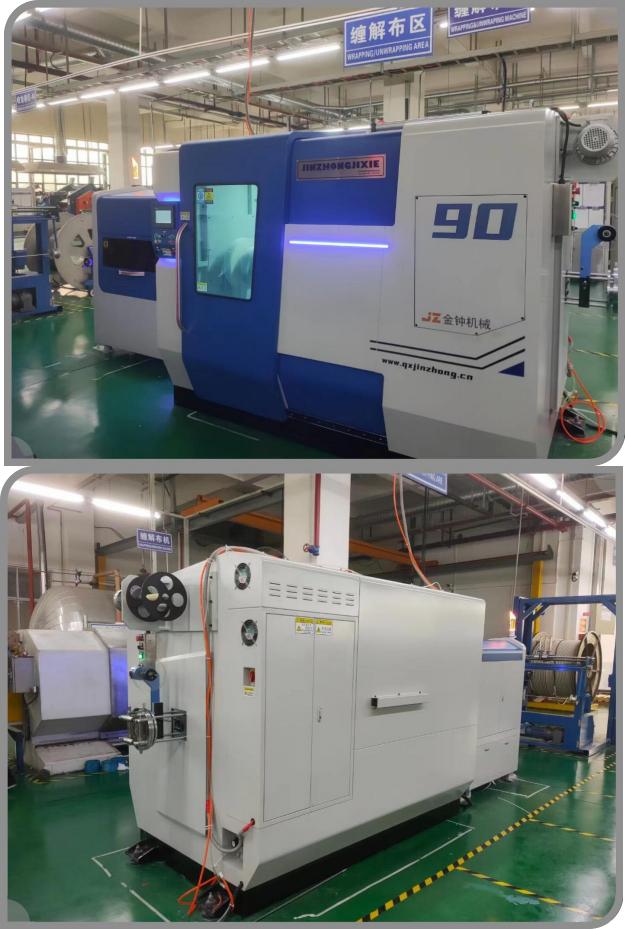

SCJ-90 series high-speed soft core wrapping and unwrapping machine

This product is a new type of wrapping and unwrapping machine developed and designed by our company. The machine adopts automatic digital control (man machine interface + PLC control), and uses servo motor to control the tension of cloth release, which greatly improves the quality of cloth wrapping; adopts the center The hanging cloth increases the capacity of one-time hanging cloth, so the work

efficiency is greatly improved (2.5-3 times higher than that of the ordinary type), the operation skills of workers are reduced, and the quality of wrapping cloth is improved. At the same time, the equipment has the function of automatic detection of no cloth and broken cloth during the working process of the equipment, which greatly improves the automation of the operation of the equipment and reduces the check-in time of the operator. It can realize that one operator can operate multiple devices at the same time to work simultaneously. It reduces the labor utilization rate of the enterprise and reduces the production cost of the enterprise.

Main technical parameters:

(1) Hose wrapping range: Φ6—Φ38mm (produced by soft core method)

(2) Spindle hole diameter: (mm) Φ90

(3) Design speed: 1000r/min

(4) Main disk working speed: (maximum) 800r/min

(5) Main functions of the equipment: used for wrapping cloth before vulcanization and unwinding cloth after vulcanization. Winding and untangling the water cloth can be done with one piece of equipment.

(6) Hanging cloth form: center hanging cloth

(7) Winding control form: automatic digital control (PLC+touch screen+servo motor)

(8) Release control form: automatic digital control (PLC+touch screen+servo motor)

(9) Tension control form: Servo motor controls the cloth tension

(10) Cloth release tension range (kg): 0kg~15kg

(11) The drive form of the whole machine: all adopt servo motors (the word film receiving machine adopts frequency conversion motors)

(12) Center height: 986mm

(13) Maximum diameter of cloth roll: 650mm

(14) Tape width (mm): 30~100

(15) Cloth belt material: Nylon cloth belt

(16) Winding pitch: (mm) 30-70

(17) Total motor power: (KW): 13KW

(18) Number of single cloth rolls installed: 4 rolls

(19) Dimensions: 4290×1540×2030 mm

(20) Protection form: fully enclosed protection room

(21) Protective cover material: stainless steel (304)

(22) Wrapping direction: The operator faces the equipment (from right to left) Note: Customers can also customize the winding direction of the equipment according to the actual use

(23) Unwrapping direction: The operator faces the equipment (from left to right) Note: Customers can also customize the winding direction of the equipment according to the actual use. No-cloth detection

function: with no-cloth detection and parking function

(24) Broken cloth detection function: with cloth broken detection parking function

(25) Door opening method: one-way

(26) Door opening drive mode: Pneumatic door opening

(27) Tractor belt material: rubber

(28) Gate control function: with gate control function. When the equipment is running normally, the safety door is opened and the equipment will automatically stop.

(29) Traction and compression method: pneumatic compression

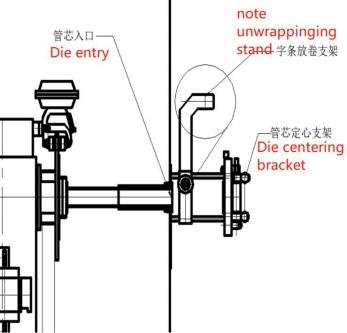

(30) Pitch adjustment method: automatic adjustment (touch screen to set) (31) Structural diagram of water distribution machine import:

3. Sub-item quantity and description:

3. Sub-item quantity and description:

|

No. |

Name |

Specification/Model |

Qty |

Unit |

Remark |

|

1 |

caterpillar |

SCJ90-1 |

1 |

set |

|

|

2 |

Wrapping and unwrapping machine |

SCJ90-2 |

1 |

set |

|

|

3 |

Cloth fixed tube |

φ20 |

1 |

pcs |

|

|

φ40 |

1 |

pcs |

|

||

|

φ55 |

1 |

pcs |

|

||

|

4 |

water cloth cover |

|

4 |

set |

|

|

5 |

Common Tools/Vulnerable Parts |

|

1 |

set |

|

|

6 |

user's Guide |

|

1 |

pcs |

|

![]() 4. Product confi uration:

4. Product confi uration:

|

Part Name |

Specification/model |

Place of origin |

Remark |

|

Spindle servo motor |

5.5kw |

Taida( DELTA) |

|

|

Traction reducer |

3kw |

Guomao( GUOMAO) |

|

|

traction servo motor |

1.5kw×2 |

Taida( DELTA) |

|

|

PLC programming controller |

|

Taida( DELTA) |

|

|

touch screen |

|

Taida( DELTA) |

|

|

control button |

|

Taida( DELTA) |

|

|

Inverter |

|

Taida( DELTA) |

|

|

Cloth release servo motor |

4.5KW |

Taida( DELTA) |

|

|

Motor |

|

Admiralty Machinery |

|

|

relay |

|

Taida( DELTA) |

|