Products

ZHG-B series High Speed Bobbin Winding Machine

ZHG-B is our compnay fourth generation full digital control high-speed steel wire plying machine independently developed and designed. It is all adopts automatic digital control (man-machine interface + PLC control).

ZHG-B series High Speed Bobbin Winding Machine

A. Product Description

ZHG-B series High Speed Bobbin Winding Machine is the fourth-generation full digital control high-speed steel wire plying machine independently developed and designed by our company. The machine all adopts automatic digital control (man-machine interface + PLC control), and the pay-off part adopts digital control and a special tension motor for pay-off, so as to ensure the precision of the pay-off tension and greatly improve the stability of the joint stock. It meets the technical requirement that the tension of the wire does not change for a long time without adjusting the tension of the wire, and its working efficiency is 3 times higher than that of the ordinary steel wire plying machine produced by our company. The quality of its joint stock meets or exceeds the technical requirements of Europe and the United States.

B. Equipment structure and function description

B1. Work of the bobbin winding machine is mainly divided into 2 parts

B1-1. The first is the pay-off part, which is composed of three parts: the pay-off frame, the pay-off panel and the pay-off control cabinet. The pay-off panel is composed of a special pay-off tension motor, a tension sensor and a pulley block. During the operation of the equipment, the real-time tension data of the tension sensor is collected by the pay-off control cabinet, and the tension motor of the pay-off is adjusted accordingly based on the collected tension data, so as to achieve the purpose of precise pay-off.

B1-2. The second is the take-up part. The take-up part is composed of a take-up straightening part, a meter recording part, a line arrangement part and a main shaft part. The take-up part is composed of man-machine dialogue touch screen, plc and servo motor. The relevant technical parameters of the equipment are set by the man-machine dialogue touch screen, and then the overall control of the operation of the equipment is carried out by the PLC, and then executed by the servo motor. Thereby the purpose of high-speed cable joint stock is completed.

B2. Main advantages of the equipment

B2-1. Fast and stable pay-off speed: The pay-off tension of the equipment is provided by a special pay-off motor. Because the braking force is mainly generated by electromagnetic induction, the advantages of this structure are no friction, no consumption, and quick response to tension adjustment during high-speed work. Therefore, the problems caused by the traditional mechanical friction mechanism that the high-speed operation cannot be performed and the tension of the wire release needs to be adjusted regularly are solved. The maximum pay-off speed can reach 10m/s.

B2-2. Uniform pay-off force: The pay-off force control of the equipment is mainly composed of a force sensor, a force controller and a force motor. During the working process of the equipment, the tension sensor is responsible for collecting the real-time pay-off tension of the steel wire, and the tension controller controls the torque of the tension motor in real time according to the collected tension data. Before the equipment leaves the factory, the manufacturer will uniformly calibrate the detection accuracy of the tension sensor and the mutual tension error, so as to achieve the purpose of uniform tension of the wire.

B2-3. The long-term stability of the pay-off force does not need to be adjusted: the pay-off mechanism of the equipment has canceled the traditional mechanical friction mechanism, so there will be no problems such as wear and tear and spring fatigue during long-term use, so there will be no wear and tear and spring fatigue. The change of tension data caused by tension fatigue, this equipment can maintain the factory tension level if there is no failure in the electrical components during the working process, and if there is a failure, the steel wire will be broken. At the same time, the tension control ability will not change with the passage of time, thus solving the user's concerns about the unstable quality of the joint stock. Let the joint stock quality be guaranteed.

B2-4. Uniform and tidy cable arrangement: The cable arrangement mechanism of the equipment uses a servo motor plus a ball screw, and the cable pitch is controlled by PLC, which greatly improves the accuracy of the cable arrangement. It solves the problem of wire dishing and crimping in the process of thread take-up of the plying machine, which ensures the quality of plying.

B2-5. Digital control system: The equipment is controlled by man-machine dialogue touch screen and PLC, which can set basic parameters such as running speed, wire pitch, and wire take-up length. At the same time, the program also provides the function of pre-setting and saving bobbin parameters. Up to 5 kinds of bobbin parameters can be preset in advance. The operator can pre-set according to the size of different bobbins, so that the program can be called quickly when changing bobbins in the future. At the same time, the system cooperates with the sensor to monitor the disconnection and record the length of the wire. A series of automatic actions, such as a series of automatic actions, greatly reduce the operator's operating skills, reduce the operating points of personnel, and improve the stability of the joint quality.

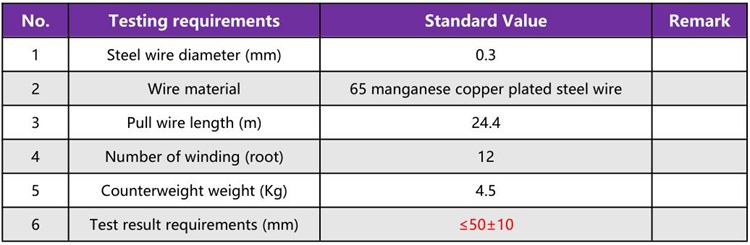

B3-6. Super-high winding quality: The winding quality is 65 manganese copper-plated steel wire with a diameter of 0.3mm as an example, and the national standard testing method is adopted. The number of winding shares is 12 strands of wire, and after winding, the elongation distance is 24.4m, the counterweight is 4.5kg, and the measured drape difference is within 50mm±10mm. So far, the data has maintained a leading level in the industry.

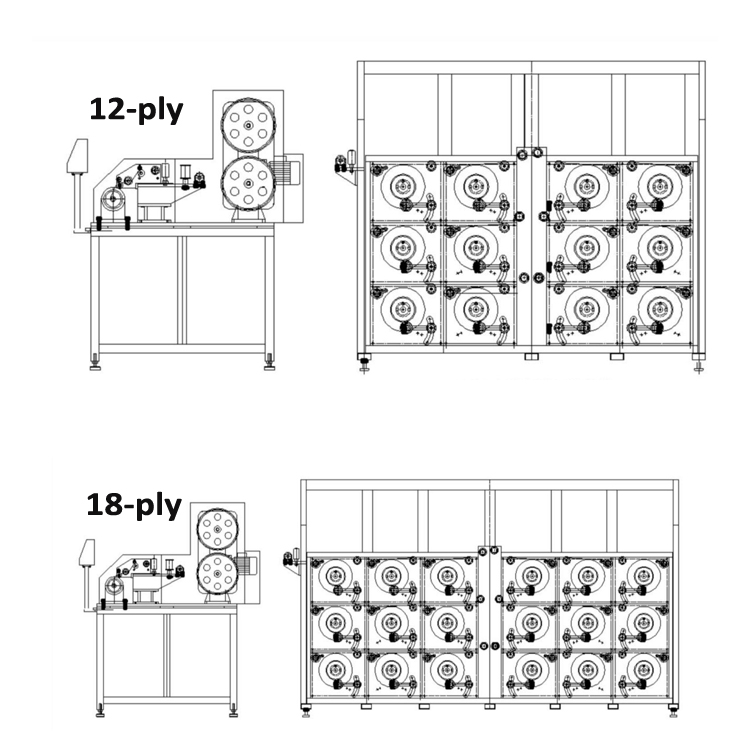

C. Machine layout

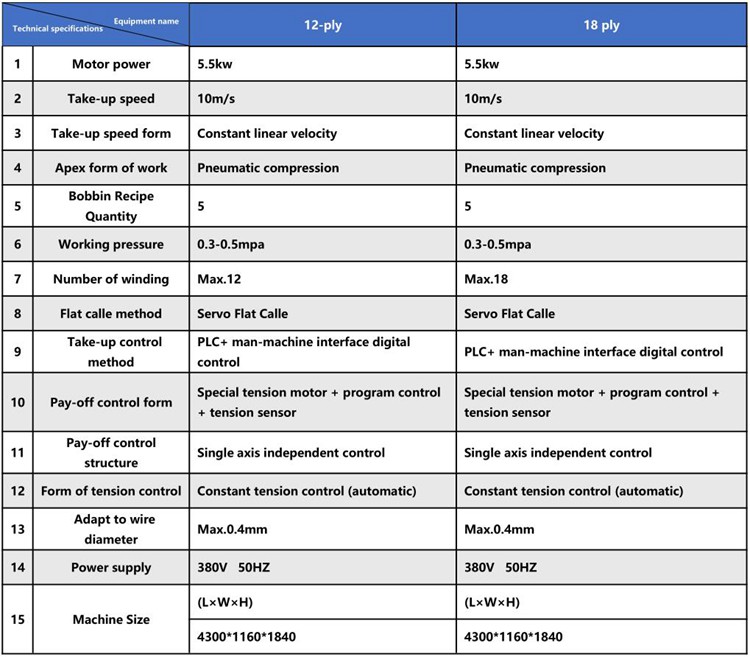

D. Technical Parameters

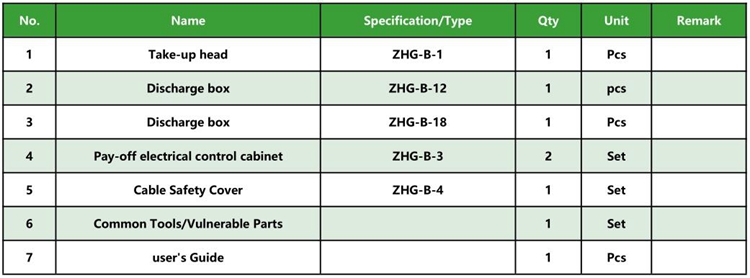

E. Sub-item Quantity and Description

F. Product Configuration

G. Main functions of bobbin winding machine

1. The take-up part adopts digital automatic control (PLC+man-machine interface)

2. Automatic pay-off tension adjustment (automatic control of pay-off tension function)

3. Automatic stop function when disconnected

4. Fixed-length take-up function

5. Three-color alarm function

6. Fault reminder function

7. Spool recipe storage function

8. The number of winding shares counting function

9. Automatic calculation function of cable pitch

10. Fault alarm recording function

K. Winding quality standard