Products

BJZD series(3×3)High Speed Wire Braiding Machine

BJZD series steel wire braiding machine is a kind of high speed 3×3 structure steel wire braiding machine developed and designed by our company for the users of middle and low end rubber hose manufacturing. Adopts automatic control, PLC + human-machine interface and servo-driven motor.

BJZD series(3×3)High Speed Wire Braiding Machine

A. High Speed Steel Wire Braiding Machine Product Description

BJZD series steel wire braiding machine is a kind of high speed 3×3 structure steel wire braiding machine developed and designed by our company for the users of middle and low end rubber hose manufacturing. Its unique 3×3 structure can increase the working efficiency by 30% compared with 2×2 structure under the same model. This machine has the advantages of easy operation, high efficiency, high precision, etc. The machine adopts automatic control, PLC + human-machine interface and servo-driven motor. It greatly improves the braiding precision and reduces the operation difficulty of workers; the fully enclosed structure reduces the noise of the equipment and improves the safety performance of workers; the large-capacity bobbin saves the waste of wire and reduces the frequency of wire change, which improves the work efficiency; the insolated layer stop alarm function and the broken wire stop alarm function; the fixed-length braiding function; the fault detection function; and the three-color alarm display.

B. Product Features

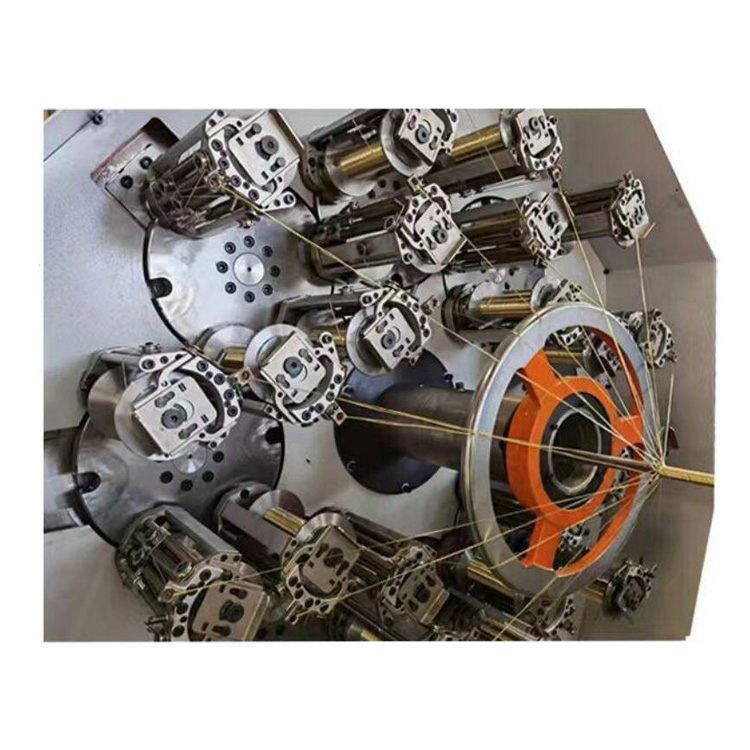

B1. This machine adopts the principle of 8-shaped curve trajectory operation, the spindle does 8-shaped throwing motion design, equipped with high-precision new structure spindle, greatly improve the quality of braiding.

B2. New spindle adopts the new two-way pulley set design, which facilitates the user to easily realize the 2-stage change of the rising force without replacing the rising force spring.

B3. The new spindle has a new high-strength design, and the maximum pay-up force can reach 30 kg. For users to cope with the daily complex and diverse braiding process to provide a solid guarantee basis.

B4. The new spindle adopts a new clutch payoff mechanism, which greatly extends the maintenance cycle of the spindle, and the daily maintenance cycle of the spindle can reach 2 years. It solves the trouble of frequent spindle maintenance for users.

B5. High rotational speed, more than 3 times of ordinary steel wire braiding machine, greatly improves the production efficiency.

B6. Large wire capacity, the net wire capacity of the bobbin can reach 9.5KG, which reduces the number of wire changes, saves wire waste and improves work efficiency.

B7. Adopting full-automatic digital control, which improves the braiding precision and reduces theoperation skills of workers, and at the same time realizes the working mode of one person operating multiple machines, which reduces the labor cost of enterprises.

B8. Supporting PLC + man-machine dialogue touch screen, which provides stable guarantee for high precision weaving.

B9. The fully enclosed sound-deadening structure guarantees the safe production of operating workers and optimizes the working environment.

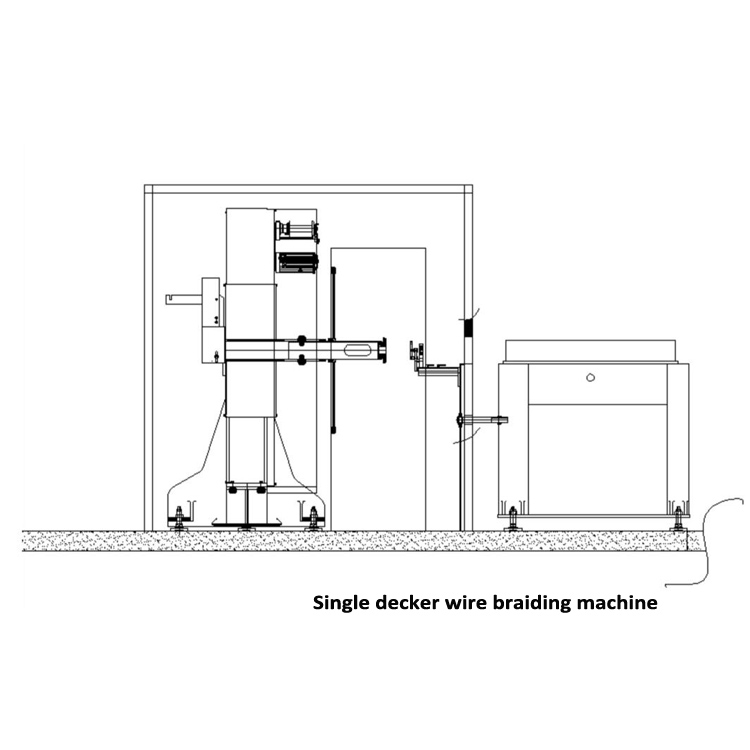

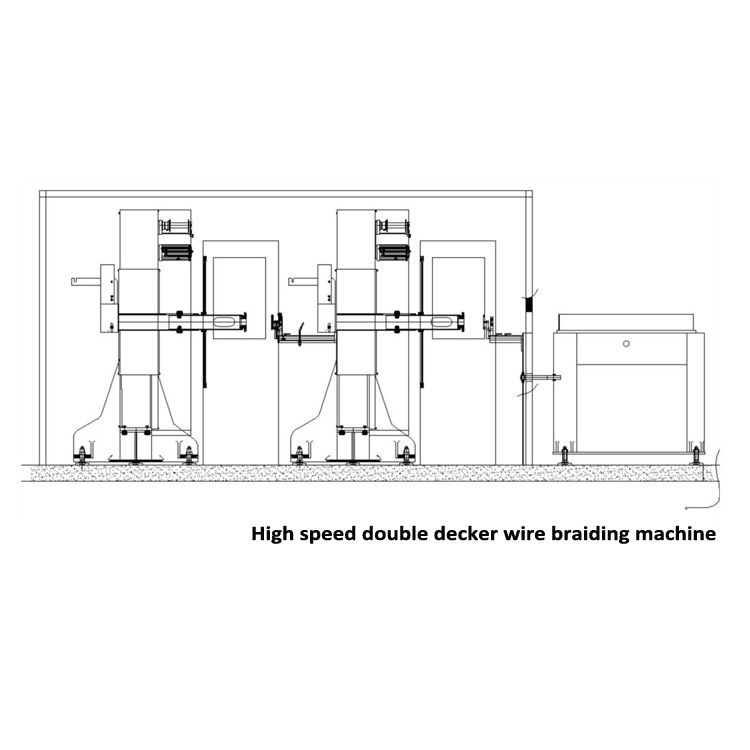

C. Machine Layout

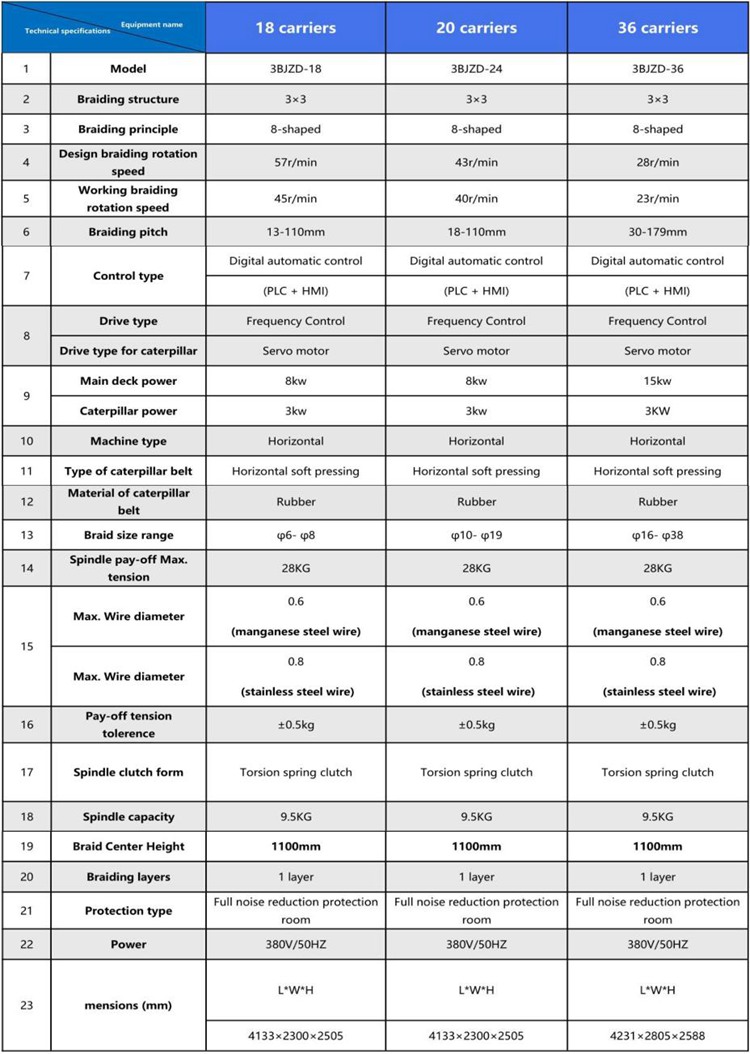

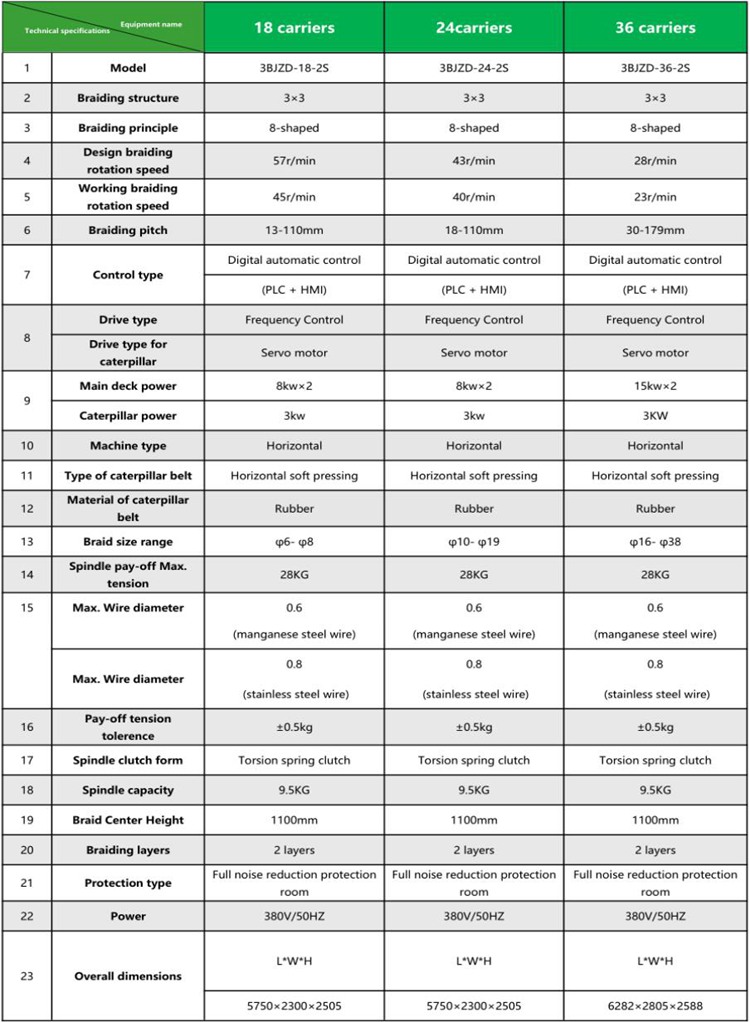

D. Main Technical Parameters

D1. Small size single decker wire braiding machine

D2. Small size double decker wire braiding machine

E. Operation Control Function

1. Full noise reduction protection room

2. Oil circuit failure automatic stop alarm function

3. Door control start/stop alarm function

4. Automatic stopping function for broken wire

5. Break in the insolated layer stop alarm function

6. Human-machine interface parameter setting

7. Fixed length braiding function

8. Three-color alarm prompt

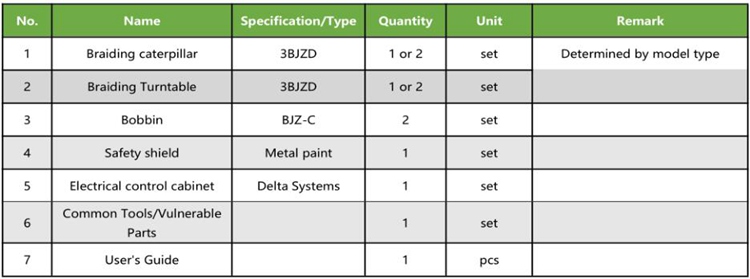

F. Itemization and description

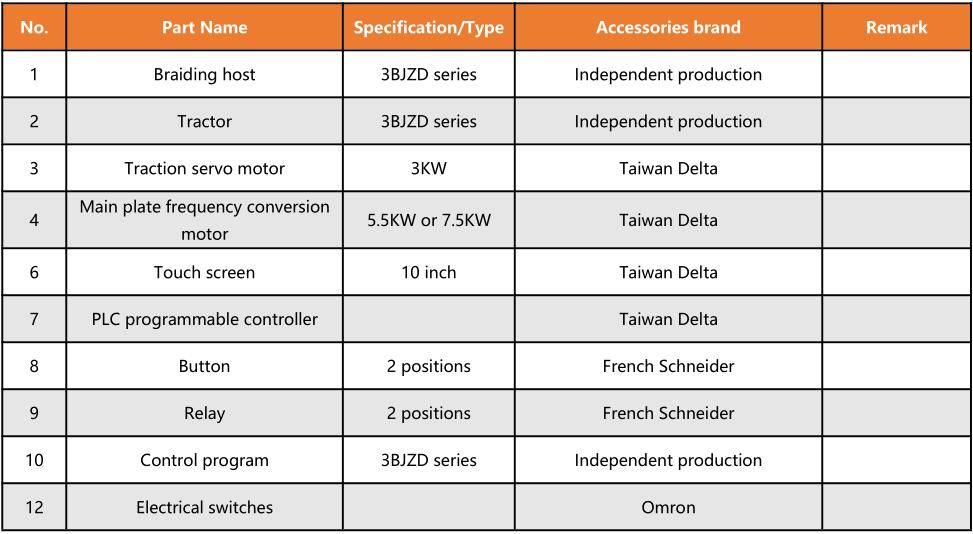

G. Product Configuration

H. Customer On-site Display