Products

BJZD series(2×2)Middle speed wire braiding machine

BJZD series steel wire braiding machine is a high-speed 2×2 structure steel wire braiding machine developed and designed by our company. Braiding range 6-8, 6-10, 10-19, 16-38, 32-102 optional.

BJZD series(2×2)Middle speed wire braiding machine

A.Product Description

BJZD series steel wire braiding machine is a high-speed 2×2 structure steel wire braiding machine developed and designed by our company. The operation is simple, the work efficiency is high, and the precision is high; the machine adopts automatic control, PLC+ man-machine dialogue interface and servo drive motor. The weaving precision is greatly improved, and the difficulty of operation for workers is reduced; the fully enclosed structure reduces the noise of the equipment and improves the safety performance of workers; the large-capacity spool saves the waste of steel wires and reduces the frequency of wire changes, and improves work efficiency; Glue stop alarm function, wire break stop alarm function; fixed-length knitting function; fault detection function; three-color alarm display.

B.Product Features

B1. BJZD series middle spped wire braiding machine adopts the principle of 8-shaped curved track operation, the spindle is designed with 8-shaped splicing movement, and is equipped with high-precision new structure spindles, which greatly improves the weaving quality;

B2. New spindle adopts a new two-way pulley block design, which is convenient for users to easily realize two-level changes in tension without replacing the tension spring.

B3. New spindle has a new high-strength design, and the maximum pay-off tension can reach 30 kg. It provides a solid foundation for users to deal with daily complex and diverse weaving processes.

B4. The new type of spindle adopts a new clutch pay-off mechanism, which greatly prolongs the maintenance cycle of the spindle, and the daily maintenance cycle of the spindle can reach 2 years. Solve the user's troubles of frequent spindle maintenance.

B5. The speed is high, which is more than twice that of ordinary steel wire braiding machines, which greatly improves the production efficiency.

B6. Large wire capacity, the net capacity of the spool can reach 9.5KG, which reduces the number of wire changes, saves the waste of steel wire, and improves work efficiency.

B7. The use of fully automatic digital control improves the knitting accuracy and reduces the operating skills of workers. At the same time, it realizes the working mode of one person operating multiple machines, which reduces the labor cost of the enterprise.

B8. Equipped with PLC+Human-computer dialogue touch screen, it provides a stable guarantee for high-precision weaving.

B9. Fully enclosed sound-absorbing structure ensures the safe production of operators and optimizes the working environment.

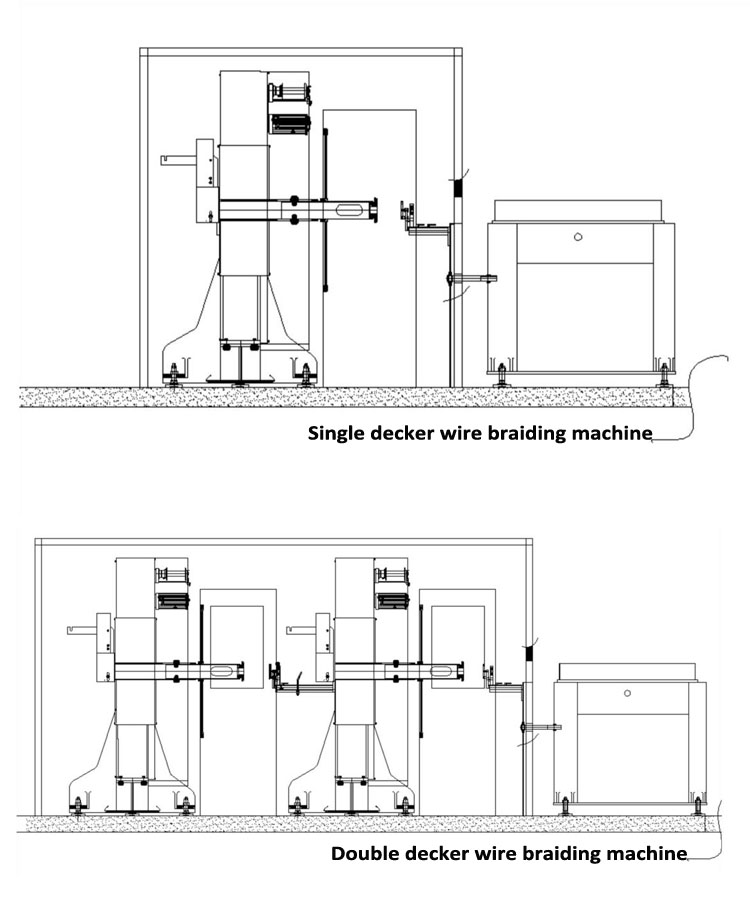

C. Machine Layout

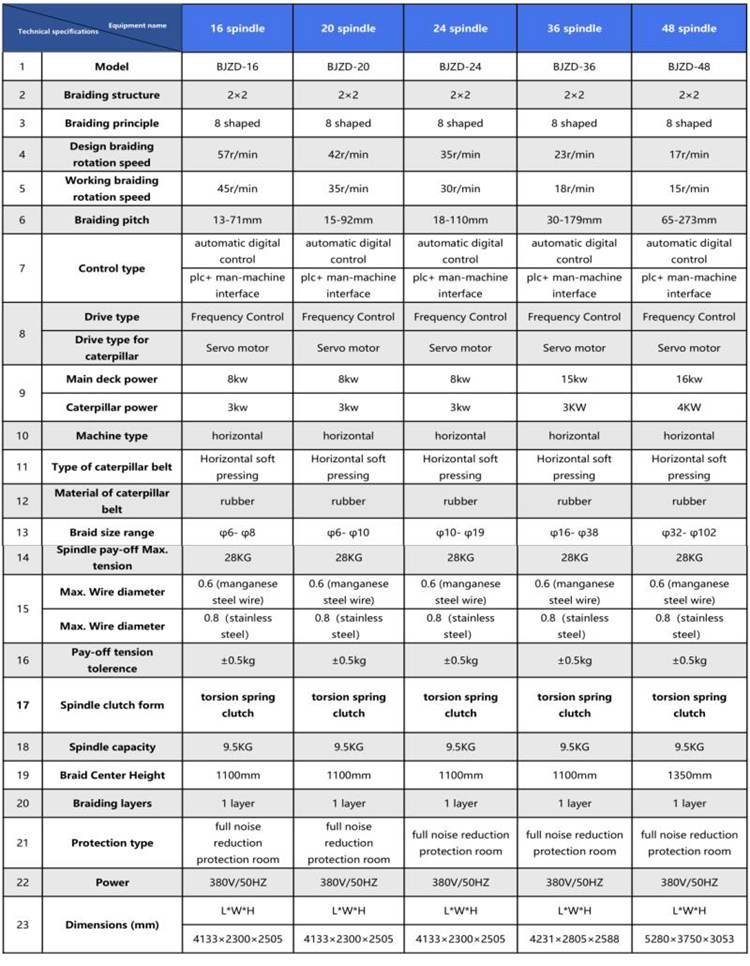

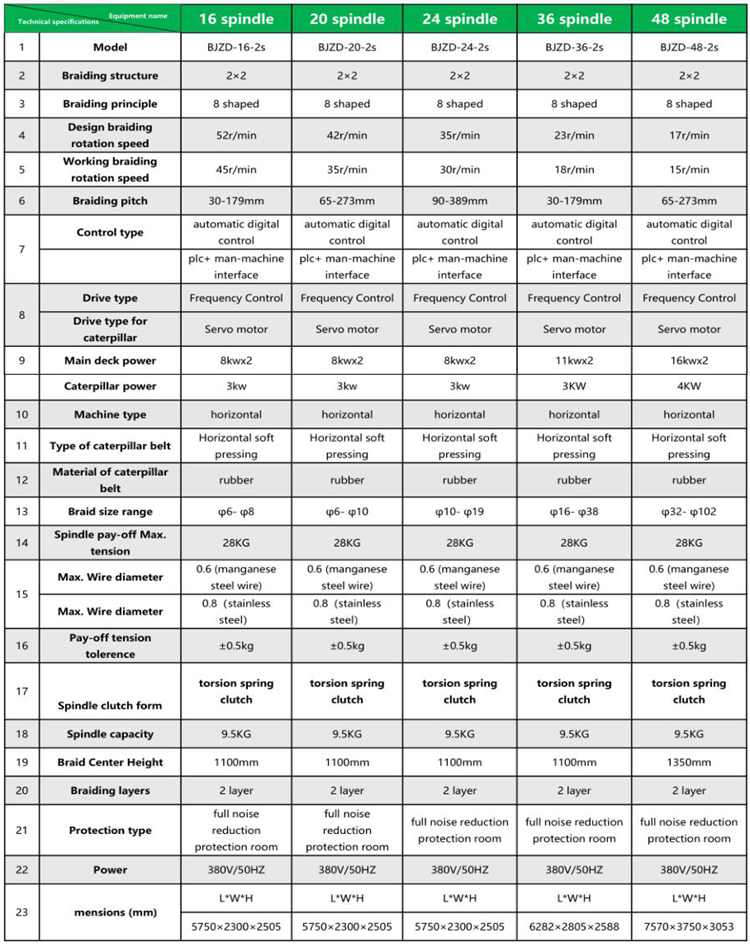

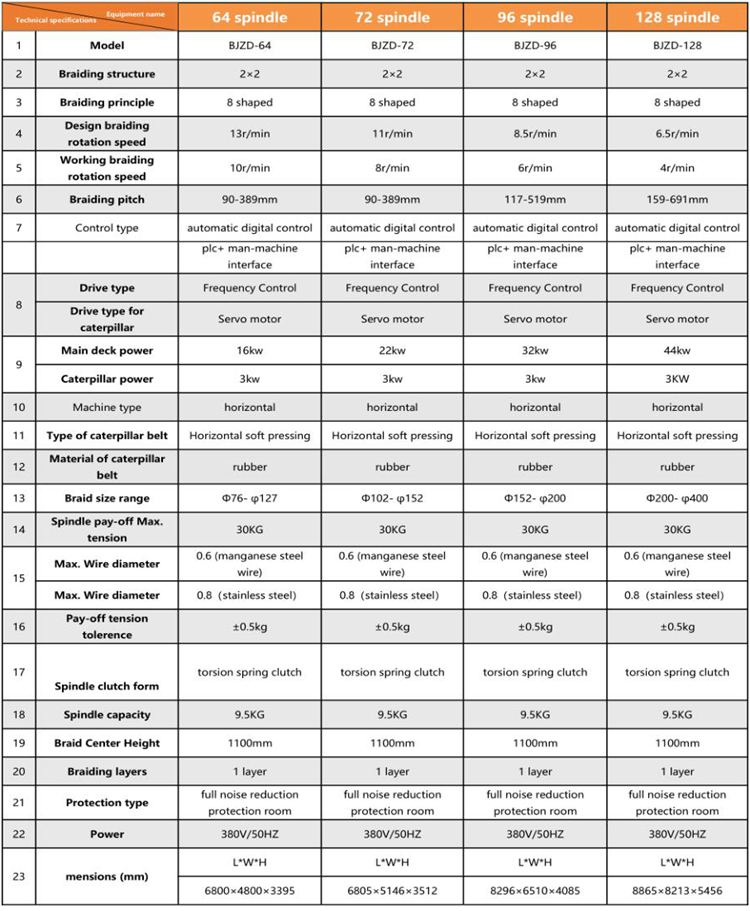

D. Main Technical Parameters

D1. Small size single decker wire braiding machine

D2. Small size double decker wire braiding machine

D3. Big size single decker wire braiding machine

E. Operation Control Function

1. Fully enclosed protection room

2. No oil supply automatic stop alarm function

3. Door control start-stop alarm function

4. Automatic parking function when disconnected

5. Stopping function when rubber breaks

6. Man-machine interface parameter setting

7. Fixed length braiding function

8. Three-color alarm prompt

F. Sub-item Quantity and Description

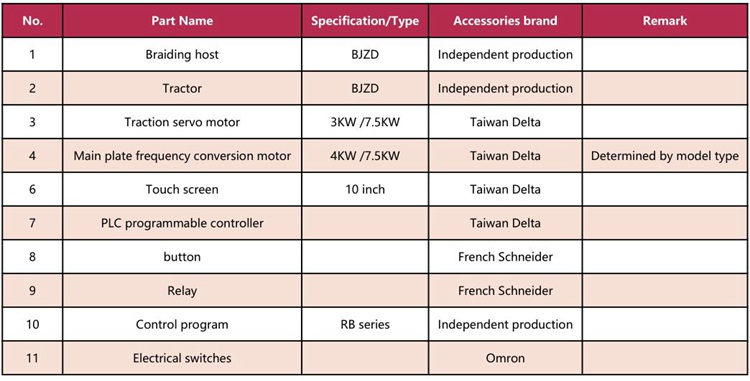

G. Product Configuration

H. User on site show